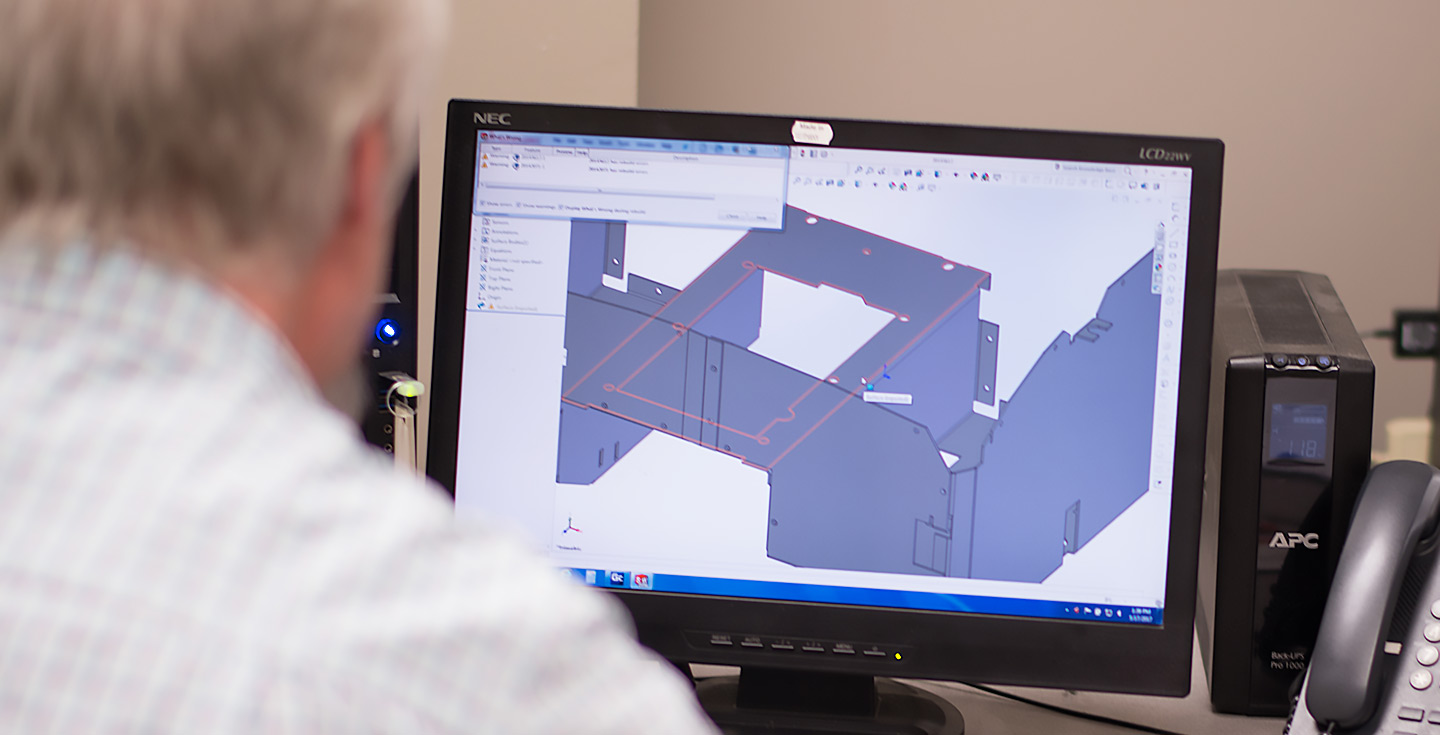

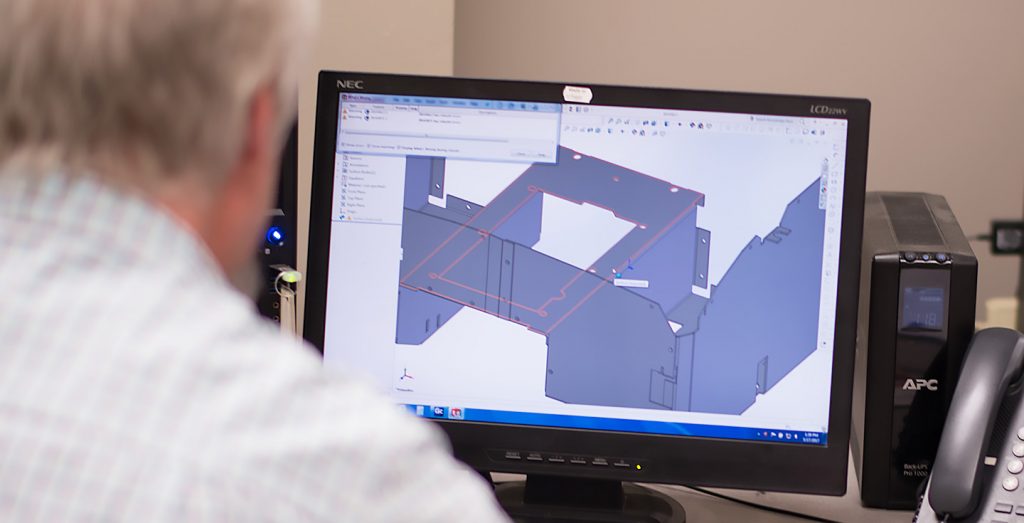

Engineering

The engineering team at Quality Fabricators, Inc. utilizes unique and advanced technology to process your product. QFI will give customer notification of tolerances and alternatives to reduce costs using existing processes. This will allow you or the designer to make better-informed decisions regarding whether or not existing manufacturing processes are able to produce the part / features as designed. Our assessment of your specifications will enable you to make an informed cost-benefit decision.

• Optimized manufacturing using design-for-manufacturability principles from customer CAD files

• Part program nesting leading to reduced material costs and higher product quality.

• Design to prototype…from your idea to a completed quality product

• Engineer, process and manufacture all of your metal fabrication, precision machining and complete assembly needs.

Featuring state-of-the-art CAD/CAM capabilities

• SolidWorks 3D Solid Modeling for design verification

• DriveWorks software for Design Automation and Product Configurator help our customers create ‘Same but Different’ products.

• Off-line programming for minimal machine downtime featuring:

• AP100US programming software for programming Punching, Laser, and CNC machines.

• GibbsCAM CNC programming needs from simple 2-axis milling and turning to complex multi-task machining

• Secure network provides revision controlled drawings and machine programs to the shop floor and for efficient set-up.

ERP System Generates:

• Complete Bills Of Material and manufacturing process flow used to produce product consistently

• Obtains process rates to maintain competitive pricing for our customers

• Material and Outside service specifications